【The third European inspection of the circular weft machine industry】Into the Rhone

2019年09月14日

On September 24, the European delegation of the China Textile Machinery Association Circular Weft Machine Industry Branch, which went all the way south, visited and inspected the headquarters of the Rhoneland Group in Italy.

Mr. Ettore Lonati, the current chairman of the Rhoneland Group, and Mr. Francesco Lonati, the general manager of the Rhoneland Company extended a warm welcome to the delegation.

Li Nuo, vice president in charge of strategic marketing and sales at Santoni (Shanghai), accompanied the visit and gave a translation explanation.

The Rhoneland Company visited by the delegation is one of the most important subsidiaries of the Rhoneland Group, mainly producing cotton socks machines and stocking machines.

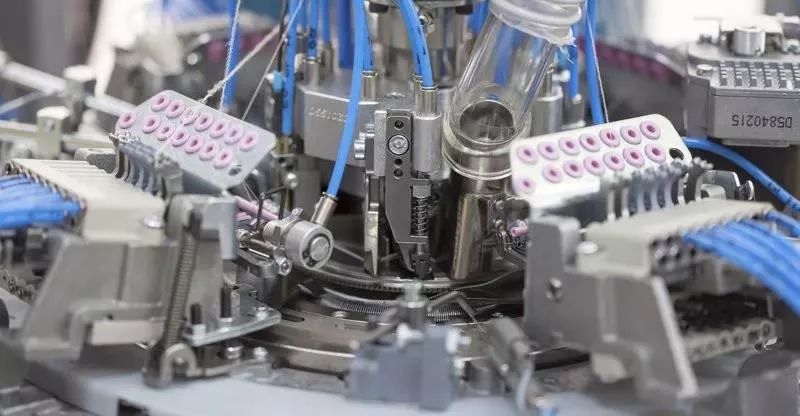

Accompanied by the general manager of Rhone, the delegation entered the sock machine production workshop and experienced the super-first-class production process. It is understood that 80% of the parts of the Rhone floor socks machine are produced by itself, and the equipment of the processing center is updated and eliminated every year to maintain the most advanced processing technology. The production capacity of the entire workshop can be as high as 50 socks machines per day.

Rhone also has very strict requirements for quality control in the production process. Only the parts that have passed the quality inspection will arrive in the automated storage system, ready to be assembled. The computer controls the storage location and method, and automatically according to the assembly demand. Judging the supply of materials, if there is a shortage, it will automatically issue instructions to the relevant departments for replenishment.

After each machine in Rhoneland is assembled, different yarns will be selected for debugging according to customer needs. The entire Rhoneland Group also has strict debugging requirements. Each sock machine guarantees at least 2 days of debugging time. Moreover, the technicians responsible for debugging will also follow the machine to the customer for installation and maintenance, so as to ensure a deep understanding of customer needs from the start of debugging.

It is particularly worth mentioning that Rhoneland has completed the research and development and application of the automatic sewing head technology of sock machines as early as seven or eight years ago, and has the patent "S BY S automatic sewing device". At present, the technology is very mature, basically Most of the sock machines that customers choose to buy are

Contains automatic sewing head device.

Looking back at the history, the Rhoneland Group was founded in 1946. In 1956, the Rhonedy showed the world the first "dual-feed" socks machine to produce women's socks. After decades of development, the Rhoneland has become a Currently the world's largest hosiery machine manufacturer and seller, with sales in more than 70 countries around the world.

The textile machinery industry is the main business of the Rhoneland Group, among which the sock machine is its founding field. Following the group's acquisition strategy, it has subsequently expanded to weft knitting seamless knitting machines, circular knitting machines, shaped packaging and finishing machinery.

In the Brescia region, where its headquarters is located, the Rhoneland Group has four factories in the field of textile machinery. Among them, the Rhoneland company mainly produces hosiery machines; Santoni company mainly produces seamless circular knitting machines; Tecnopea company mainly produces finishing and finalizing. Packaging equipment; while the company Dinema specializes in the development and production of electronic control systems and software applications.

Santoni (Shanghai), which we are familiar with, is one of the subsidiaries of the Rhoneland Group. Fifteen years ago, Santoni began to deploy in the Chinese market, and established Santoni (Shanghai) in 2004. At that time, the Shanghai factory was mainly responsible for the production of seamless knitting machines. With the completion of the Santoni Industrial Park covering an area of 200 acres, the group moved all the production and installation of circular knitting machines to Shanghai, as well as the production of some socks machines. During this period, Santoni (Shanghai) also strategically acquired Jingmei Machinery, a large circular knitting machine manufacturer, South Korea's Susan, a sock machine manufacturer, Hengsheng, a seamless underwear machine manufacturer, and some circular knitting machine accessories suppliers in China. . After completing these series of layouts, Santoni (Shanghai) has become the largest production base of the Rhoneland Group outside Italy, with an annual production capacity of 3,000 seamless knitting machines, 2,500 circular knitting machines and 5,000 sock machines.

During the visit, the China Textile Machinery Association Yuanwei Industry Branch presented the Rhoneland Group with a gift of ceramics with Chinese characteristics.

Page Up

Related News